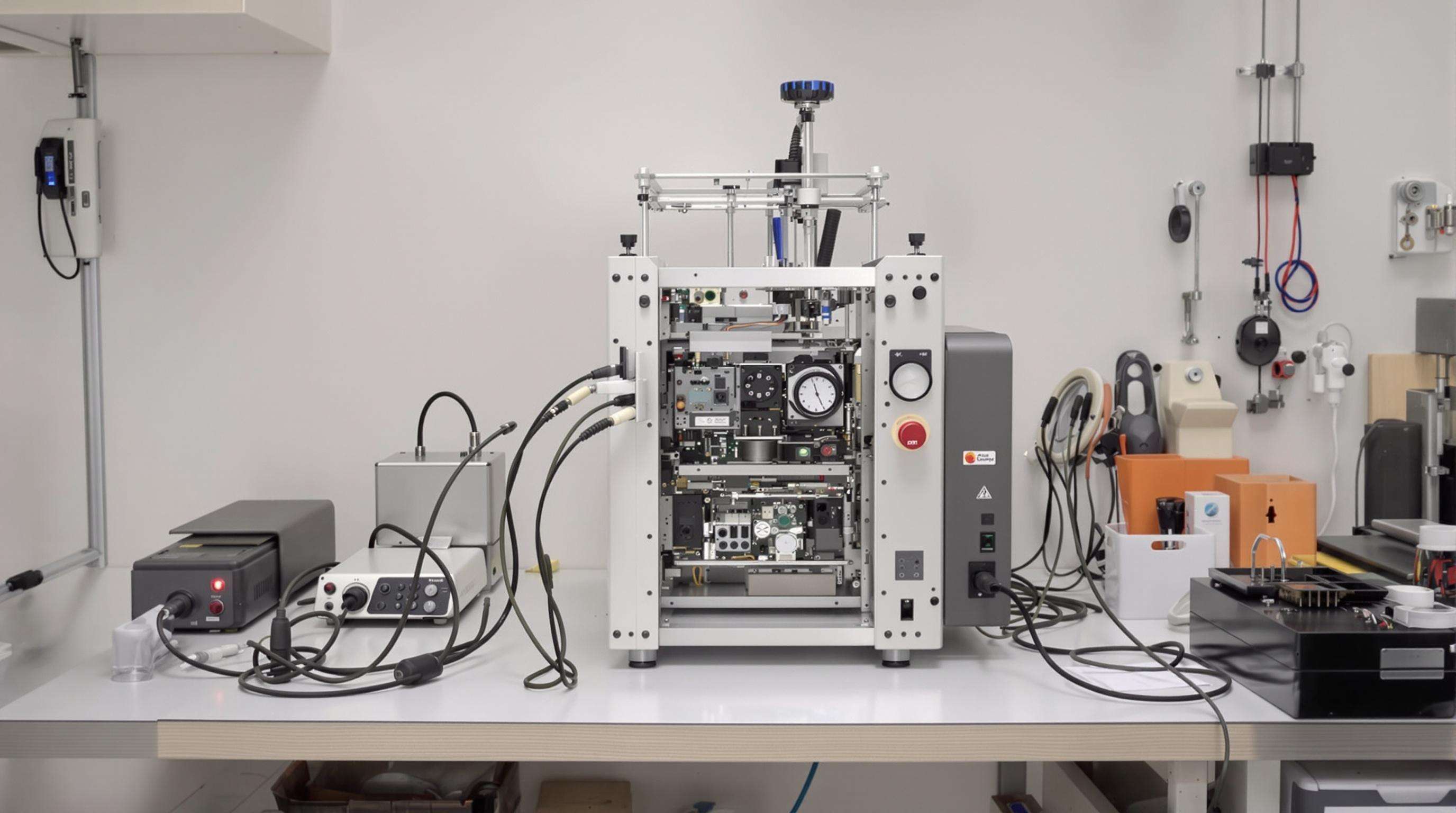

Small electronics repair shops and prototype labs are getting serious about making the most of their limited floor space these days. That's why many are switching to benchtop automatic soldering machines which take up about 40% less room compared to older models. Shops operating in spaces smaller than 500 square feet find they get much better value from compact systems too - around 80% utilization rate versus just 55% when using those big bulky machines. This trend is helping urban microfactories thrive since they need decent soldering power but don't have luxury of separate machine rooms. Some startups in city centers actually manage entire production lines in converted garages thanks to these space-saving solutions.

Industry analysis reveals a compound annual growth rate (CAGR) of 22% for compact automatic soldering systems since 2020, outpacing the broader industrial machinery market by 9 percentage points. The 68% cumulative adoption surge correlates with measurable improvements:

These outcomes highlight a strategic move from manual stations to compact automation that fits constrained layouts.

Modern 14"–14" automatic soldering machines now achieve 98% thermal efficiency parity with full-sized units through three innovations:

A 2023 field study showed compact models completing 220 precision solder joints/hour versus 180 in larger machines, proving that small-scale automation can boost productivity while conserving space.

When designing new equipment, engineers turn to sophisticated computer modeling tools to cut down on empty air pockets inside machinery. The result? Modern compact versions take up around 62% less room on factory floors compared to older designs according to industry data from last year's benchmark report. Many manufacturers now incorporate vertical stacking solutions along with those handy modular soldering components that still pack all necessary functions into small footprints. For smaller workshop setups especially, benchtop models come equipped with clever cable organizers that tuck away when not needed plus fold out storage areas. These features make a huge difference for repair shops operating in spaces under 500 square feet where every inch counts toward keeping things neat and productive without sacrificing essential tools.

The embedded microprocessors provide around plus or minus 0.01 degrees Celsius temperature accuracy through 18 different programmable profiles, which is comparable to what we see in full scale industrial equipment. When it comes to thermal management, these systems offer real time feedback that tweaks power levels approximately 400 times every second. This helps maintain good quality joints even when working in tight spaces where traditional methods might struggle. According to research published by MIT Robotics back in 2022, smaller units equipped with built in vision technology managed to hit nearly 98.4 percent accuracy for placing solder correctly. That's actually quite impressive considering they beat manual work by over half in those cramped conditions most factories face daily.

Aerospace-grade aluminum alloys and carbon-fiber composite frames reduce weight by 40% while increasing torsion resistance 3.2– over steel. Multi-layer ceramic heating elements endure 18,000 thermal cycles without degradation, validated by the International Materials Institute (2024). These advancements support a 15,000-hour mean time between failures (MTBF)–on par with full-sized systems–despite reduced size.

A Portland-based repair facility increased throughput by 40% after adopting automatic soldering machines (2023 case study). Technicians completed 27–32 complex PCB repairs daily, up from 19–22 with manual methods, while maintaining 99.4% joint integrity. Programmable profiles cut setup time between jobs by 65%, demonstrating that compact automation can scale with diverse production needs.

Operators report 48–52% fewer cold joints and bridging errors using automatic machines compared to manual soldering (2024 Soldering Quality Benchmark). Microsecond-level thermal monitoring prevents component damage, with error rates below 0.7% across 12,000+ joints in stress testing. This precision reduces rework time by 8–11 hours weekly in typical small workshops.

| Metric | Automatic Machines | Manual Soldering |

|---|---|---|

| Speed (joints/hour) | 220-260 | 70-90 |

| Temperature Accuracy | ±1.2°C | ±8-15°C |

| Consistency (σ) | 0.04mm | 0.31mm |

| Training Time | 6-8 hours | 120+ hours |

Recent data shows automatic machines deliver 5.9– faster cycle times and 88% less variability in solder volume–essential for high-density PCBs and miniaturized components.

Modern compact models endure 14,000+ operating hours in accelerated testing (2022 Durability Study). Advanced ceramic heating elements maintain stability through 95,000+ heating cycles–equivalent to 6–8 years of continuous use. Properly maintained units show less than 5% performance degradation after 24 months, matching the longevity of full-sized industrial systems.

Microprocessor-controlled heating systems maintain ±1°C accuracy over 8-hour shifts using thermocouple sensors and PID algorithms, preventing thermal overshoot. A 2024 Material Processing Study found this precision reduces solder joint defects by 34% compared to manual irons, while optimizing heat transfer cuts energy use by 18%.

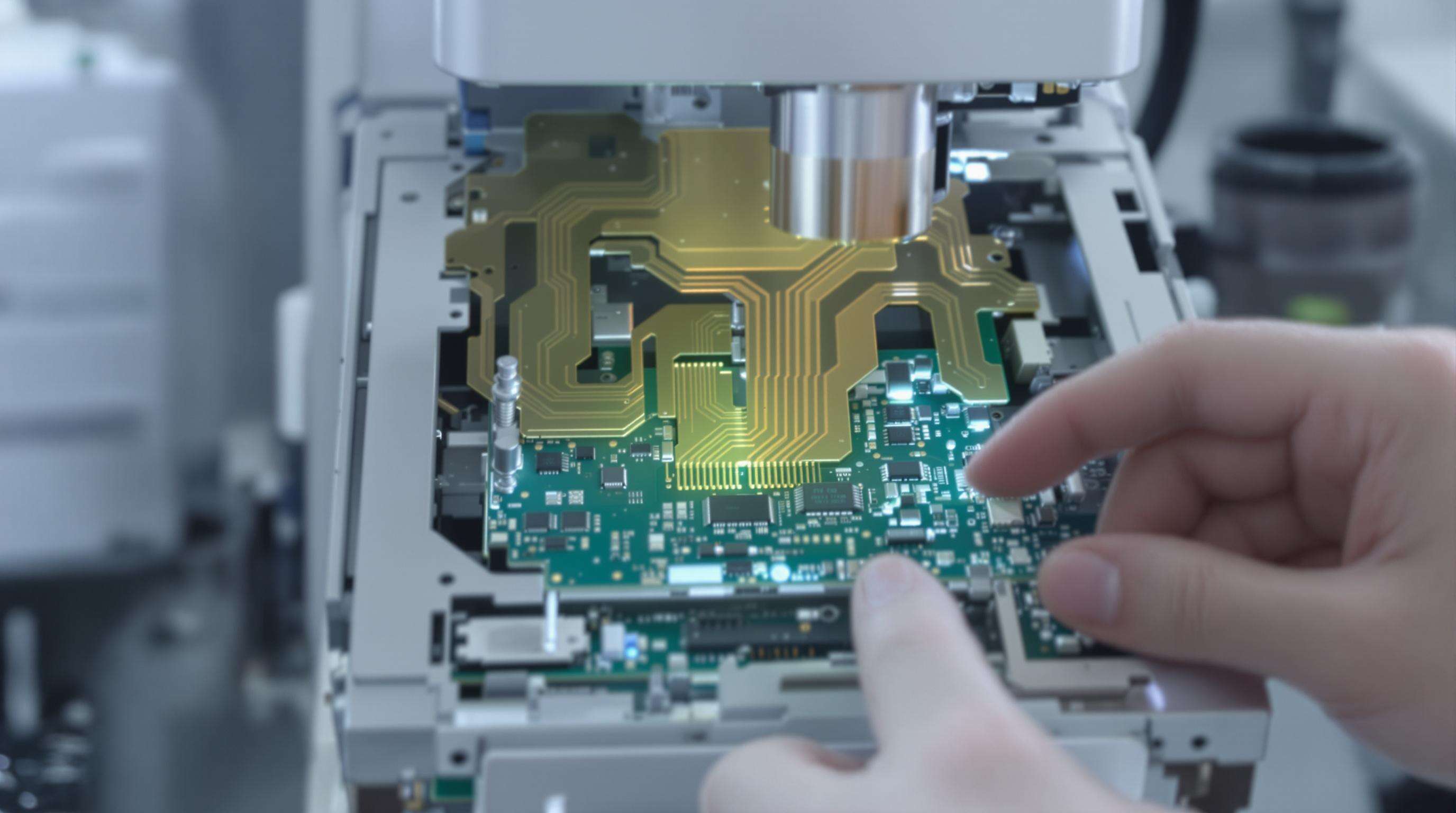

Machine vision systems map PCB layouts at 120 FPS with 5-micron resolution. When paired with self-learning algorithms, they achieve 99.2% component placement accuracy–27% higher than 2020 models. This eliminates manual path programming, allowing job reconfiguration in under 90 seconds via simple CAD uploads.

Ceramic core heaters with graphene coatings offer 40% faster thermal recovery than nichrome elements. Combined with auto-sleep modes activating after 30 seconds of inactivity, these reduce standby power consumption by 72% (Industrial Energy Metrics 2023). Workshops save $1,200+ annually per machine, with no compromise on peak performance.

Compact automatic soldering machines are evolving rapidly to meet demands for miniaturization and smarter manufacturing. Analysts project a 30% increase in benchtop model adoption by 2027 as workshops prioritize space efficiency without sacrificing output. These shifts reflect broader movements toward sustainable, connected production ecosystems.

Manufacturers are shrinking footprints while enhancing precision. New benchtop models support micro-soldering for components under 0.2mm, meeting needs in medical and aerospace fields. Advanced laser systems and vertical workspace designs enable 40% smaller footprints than traditional units.

The push for RoHS-compliant processes has accelerated adoption of lead-free alloys and biodegradable fluxes. A 2024 industry survey found 72% of manufacturers use low-energy soldering profiles, cutting power use by up to 25%. Modular construction also supports component recycling, aligning with circular economy goals.

Cloud-connected sensors now track thermal performance and tip wear in real time. Facilities using IoT-enabled systems achieve 92% equipment uptime through continuous monitoring. Predictive algorithms analyze usage patterns to schedule maintenance before failures occur, reducing downtime costs by $18k annually per machine.

Compact automatic soldering machines help save space, improve workstation reconfiguration speed, reduce energy costs, and enhance operator satisfaction due to space-saving designs.

These machines use microprocessor-controlled heating systems and PID algorithms, which enable precise temperature control and real-time feedback, maintaining temperature accuracy within ±1°C.

Yes, compact soldering machines use advanced materials like aerospace-grade aluminum and carbon-fiber composites that enhance durability, achieving a mean time between failures comparable to full-sized systems.

Future trends include increased adoption of benchtop models, advancements in miniaturization, sustainability with lead-free soldering, and IoT integration for remote monitoring and predictive maintenance.