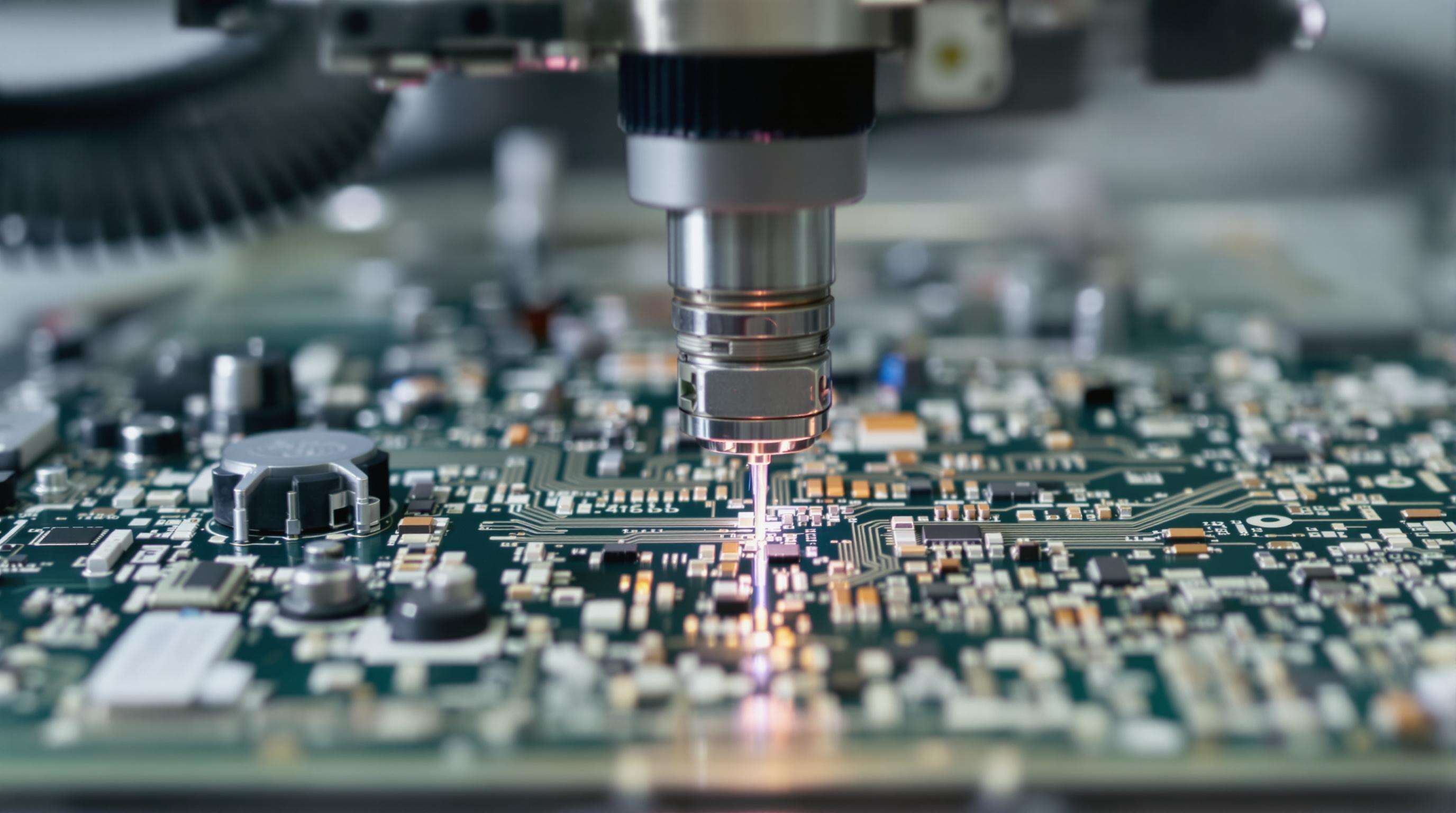

Military defence systems including encrypted radio modules and missile guidance PCBs require solder joints positional accuracy of less than 0.25mm to ensure signal integrity under the harshest conditions. This precision is required as per IPC-A-610 Class 3 specifications for military electronics, which enables adoption of automatic wire soldering machines of the order of 50μm repeatability. This reduces the occurrence of microvoids and intermetallic fractures that can sideline thermal imaging systems or UAV control boards under operational stress.

Advanced systems utilize real-time thermal profiling and pressure-controlled solder heads to maintain optimal joint formation parameters:

| Parameter | Manual Soldering | Automated System |

|---|---|---|

| Temperature Delta | ±25°C | ±1.5°C |

| Solder Volume CV | 18-22% | 2-3% |

| Placement Accuracy | 0.5mm | 0.05mm |

This control enables First Pass Yield improvements from 82% to 99.6% in defense contract manufacturing, critical for phased array radar components with 15,000+ interconnects.

Automatic wire soldering machines reduce error rates to 0.02 defects/kJoint through:

This reliability proves critical in nuclear command systems where single defects could compromise encrypted data transmission.

Operators guide robots through soldering sequences using intuitive interfaces, reducing programming time by 67% compared to traditional code-based systems (NIST 2022). The approach enables rapid adaptation between QFN-48 package soldering and through-hole connector assembly.

Technicians remain essential for:

Facilities combining AI-driven robots with expert monitoring achieve 89% fewer cold joints compared to fully automated lines (Aberdeen Group 2023).

A North American aerospace manufacturer achieved:

Advanced soldering cells maintain consistency through:

Defense contractors report 41% reduction in rework hours when combining automation with skilled process engineers (SAE International 2023).

Automatic systems maintain ±0.05mm positional accuracy from prototypes to 10,000-unit runs, critical for less than 0.3mm solder joint tolerances.

Modern machines document:

Automated systems achieve 99.97% compliance with J-STD-001H versus 89% in manual processes (IPC 2022).

While requiring 3-5× higher initial investment, automated systems demonstrate:

Predictive maintenance extends MTBF to 14,000 hours, surpassing military electronics service life requirements.

±0.1°C thermal stability prevents cold joints, adjusting power delivery within 50ms of detecting issues – critical for 99.8% joint consistency in radar systems.

Neural networks predict optimal paste volumes with 94% accuracy, eliminating 11-hour production delays per design change in missile guidance PCBs.

Vibration analysis detects nozzle wear 85 hours before failure, reducing machine-related defects from 1,200 PPM to 340 PPM while extending tip lifespan by 70%.

Virtual system replicas enable real-time analysis, achieving 99.96% joint conformity versus 98.4% in conventional setups.

5-micron resolution detects pad oxidation and lead coplanarity issues invisible to human operators, vital for mix-technology PCBs.