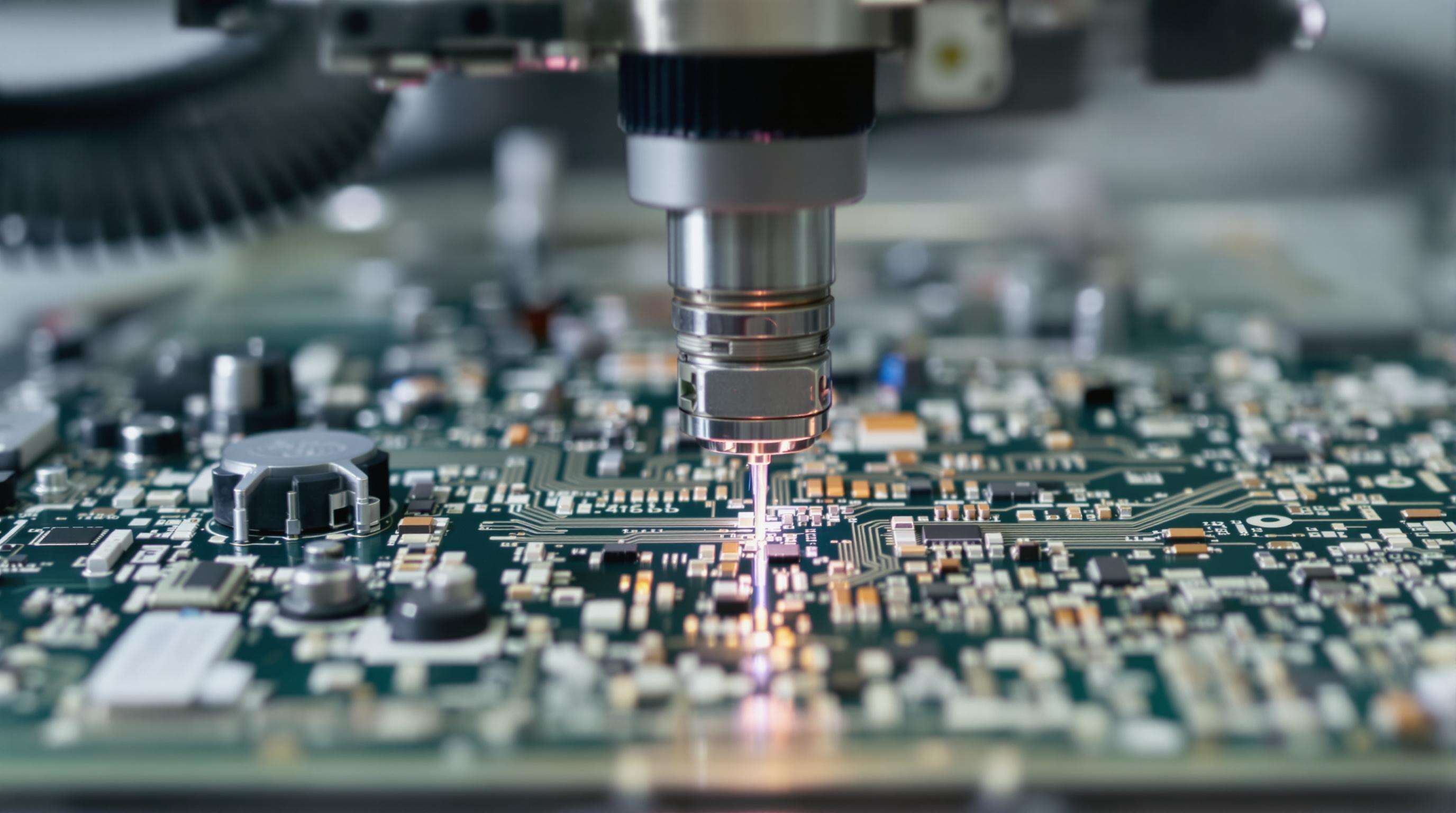

מערכות הגנה צבאיות, כולל מודולי רדיו מוצפנת ומערכות PCB להנחיית טילים, דורשות דיוק במיקום של חיבורי הסולדרים בפחות מ-0.25 מ"מ כדי להבטיח שלמות אות גם בתנאים הקשים ביותר. דיוק זה נדרש על פי מפרט IPC-A-610 Class 3 לאלקטרוניקה צבאית, מה שמאפשר אימוץ של מכונות סולדרת חוט אוטומטיות עם חזרתיות של 50 מיקרון. הדבר מפחית את הופעתם של מיקרו-חורים ושברים בין מתכתים שעלולים להוציא מהפעלה מערכות טרמיות או שלטי בקרת UAVים תחת מתח פעולה.

מערכות מתקדמות משתמשות בפרופיל טמפרטורה בזמן אמת ובראשי חיבוט עם שליטה בלחץ כדי לשמור על פרמטרים אופטימליים של היווצרות החיבורים:

| פרמטר | לוטוש ידני | מערכת אוטומטית |

|---|---|---|

| הפרש טמפרטורה | ±25°צ | ±1.5°צ |

| סטיית נפח החיבוט | 18-22% | 2-3% |

| דיוק הנחתה | 0.5mm | 0.05 מ"מ |

שליטה זו מאפשרת שיפור של First Pass Yield (היוון מוצלח בפעם הראשונה) מ-82% ל-99.6% בייצור עבור contrats ביטחוניים, מה שקריטי לרכיבי רדאר פאזה עם 15,000 חיבורים ומעלה.

מכונות אוטומטיות לחיבוט תילים מפחיתות את שיעור השגיאות ל-0.02 פגומים/אלף חיבורים באמצעות:

אמינות זו היא קריטית במערכות פיקוד גרעיניות, בהן פגם בודד עשוי לפגוע במעבר נתונים מוצפנת.

מפעילים מדריכים רובוטים לאורך סדרת הלחמה באמצעות ממשקים אינטואיטיביים, מצמצמים את זמן התכנות ב-67% בהשוואה למערכות מבוססות קוד מסורתיות (NIST 2022). הגישה מאפשרת התאמה מהירה בין לחימת אריזות QFN-48 לבין הרכבת מוצבי חור חודר.

טכנאים מהווים חשובים עבור:

מתקנים המשלבים רובוטי בינה מלאכותית עם פיקוח מומחה מ loggin 89% פחות מפרקים קרים בהשוואה לקוים אוטומטיים לחלוטין (קבוצת אברדין 2023).

יצרן צפוני אמריקאי של מוצרי תעופה וחלל השיג:

תאי לחימר מתקדמים שומרים על דיוק באמצעות:

קבלני הגנה מדווחים על ירידה של 41% בשעות עבודה חוזרת כאשר משלבים אוטומציה עם מהנדסי תהליך מוכשרים (SAE International 2023).

מערכות אוטומטיות שומרות על דיוק מיקומי של ±0.05 מ"מ, מה שממש חשוב עבור סובלנות של פחות מ-0.3 מ"מ במחברים לולתיים.

מכונות מודרניות יוצרות מסמכים:

מערכות אוטומטיות מ logות 99.97% עמידה בתקן J-STD-001H לעומת 89% בתהליכי ידנית (IPC 2022).

בעוד שהשקעה האולית גבוהה ב-3-5×, מערכות אוטומטיות מציגות:

תפעול מונחה תחזוקה מאריך את MTBF ל-14,000 שעות, מעבר לדרישות חיי השירות של האלקטרוניקה הצבאית.

יציבות תרמית של ± 0.1°C מונעת מפרקים קרים, התאמת אספקת כוח בתוך 50ms של גילוי בעיות קריטית ל-99.8% עקביות מפרקים במערכות רדאר.

רשתות עצבים חוזה נפח הדבק האופטימלי עם דיוק 94%, חיסול עיכובים ייצור של 11 שעות לפי שינוי עיצוב ב- PCBs הנחיה טיל.

ניתוח הרטטים מגלה גירוד של הפקק 85 שעות לפני כישלון, מקטין פגמים הקשורים למכונה מ 1,200 PPM ל 340 PPM תוך הארכת חיי הקצה ב 70%.

העתקות מערכות וירטואליות מאפשרות ניתוח בזמן אמת, השגת 99.96% תאימות משותפת לעומת 98.4% בהגדרות קונבנציונליות.

רזולוציה של 5 מיקרונים מגלה חמצון של סדינים ובעיות קופלנריות עופרת בלתי נראות למפעילים אנושיים, חיוניות עבור PCBs טכנולוגיות מעורבות.