Elektronicafabrikanten zijn het punt van non-return gepasseerd: Drieëntachtig procent van de industriële OEM's die IDC-analisten onlangs ondervroegen, vertrouwde op batchspecifieke draadconfiguraties (Ponemon 2023). HMLV (High Mix, Low Volume) productie doet precies dit door flexibele werkstromen te gebruiken die zijn ontworpen voor constante productvariatie, in sterk contrast met massaproductie. Dit bleek een gamechanger te zijn, aangezien automatische draadsoldeermachines de sleutel werden en meer dan 100 varianten per dag konden verwerken zonder in te boeten aan nauwkeurigheid.

Markten variërend van medische implantaten tot industriële IoT vereisen bedradingoplossingen die zijn afgestemd op specifieke spanningslimieten, ruimtelijke beperkingen en omgevingsomstandigheden. Voorbeeld:

Deze verandering maakt productie-reeksen van 10.000 eenheden verouderd. Fabrikanten voeren tegenwoordig snelle prototyping-cycli uit—soms zelfs van CAD-ontwerp naar functionele samples in minder dan 8 uur.

Handmatig lassen van bedrading heeft moeite om <0,5% defecten te behouden wanneer er 5-10 ontwerpveranderingen per ploeg worden verwerkt. Veelvoorkomende problemen zijn:

| Uitdaging | Impact | Geautomatiseerde oplossing |

|---|---|---|

| Inconsistenties in soldeerverbindingen | toename van het veldfaalpercentage met 6,5% | Gesloten thermisch regelsysteem |

| Configuratiefouten | 12-18 minuten herwerk per fout | RFID-gestuurde gereedschapshoofdverificatie |

De verschuiving in de automobielindustrie naar op maat bestelde EV's toont deze noodzaak aan—voornaamste fabrikanten realiseren 112 dagelijkse ontwerpwijzigingen met modulaire automatische draadsoldeersystemen.

Massaproductiekosten lopen uit de hand bij batches onder de 500 eenheden—instelkosten nemen 72% van de prijs per eenheid in beslag vergeleken met 9% in HMLV-geoptimaliseerde cellen. Een prototypebatch van 50 onderdelen in autowiring vereist:

Traditionele lijn

HMLV-automatisering

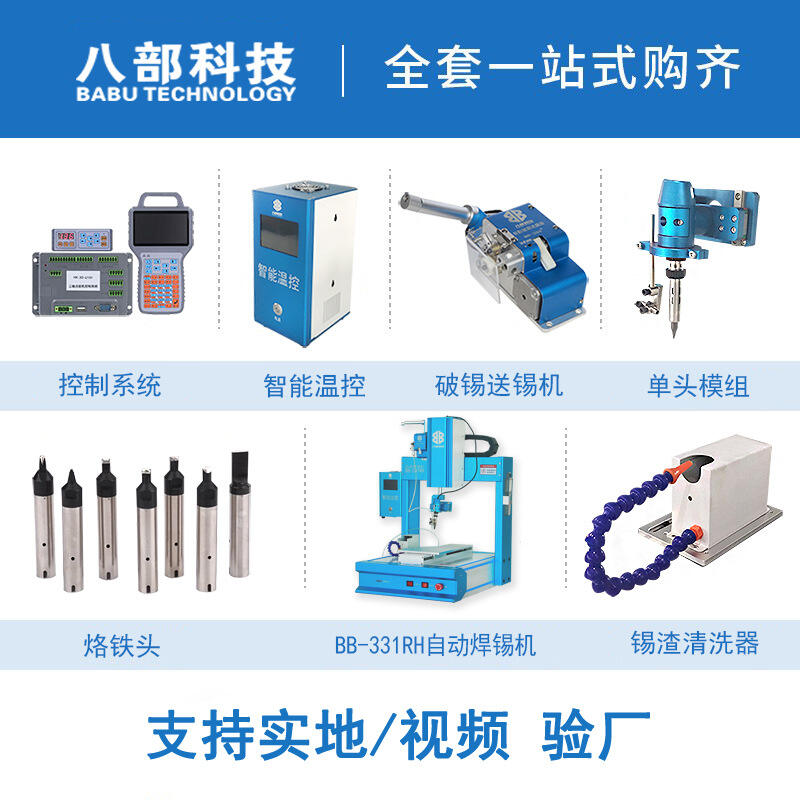

Automatische draadsoldeermachines nemen de engineeringuitdagingen van vandaag de dag het hoofd door realtime herprogrammering mogelijk te maken zonder productievertragingen. Deze systemen integreren direct met CAD/CAM-platforms zoals Autodesk Fusion 360 om bijgewerkte schema's binnen enkele minuten om te zetten in uitvoerbare instructies.

De precisie van adaptieve regelsystemen garandeert dat elke soldeerverbinding een positioneringsnauwkeurigheid van ±0,01 mm behoudt, zelfs bij het verwerken van:

Moderne automatische draadsoldeermachines bereiken piekprestaties dankzij adaptieve regelsystemen die voortdurend de productievariabelen monitoren en verfijnen.

Adaptieve soldeersystemen gebruiken multisensorarrays om temperatuur (±1°C), lodet hoeveelheid (±0,01 ml) en verbindingalignement (5μm nauwkeurigheid) te volgen. Bij afwijkingen voert het geslotenloopsysteem correcties uit binnen 50ms - sneller dan menselijke operators fouten kunnen waarnemen.

Belangrijkste mogelijkheden:

Deep learning algoritmen analyseren historische procesgegevens en real-time inspectieresultaten om de betrouwbaarheid van verbindingen te voorspellen. Getraind op 850.000+ soldeerverbindingen behalen deze modellen 94% nauwkeurigheid bij het voorspellen van foutgevoelige verbindingen vóór elektrische tests.

| Procesfase | Traditionele methode | ML-verbeterde methode |

|---|---|---|

| Foutdetectie | Postproductietests | Realtime voorspellingen |

| Fout-positiefpercentage | 12% | 2,8% |

Adaptieve controllers reconfigureren automatisch de machineparameters voor verschillende kabelboomontwerpen, waardoor de wisseltijd met 78% wordt gereduceerd vergeleken met handmatige methoden.

Een toonaangevend fabrikant van medische apparatuur stond voor uitdagingen met 1.200+ kabelboom-SKUs en een voorspelbaarheid van de vraag onder de 42%. Traditionele batchproductie leidde tot 23% verloren componenten door vervaldatumverloop.

De fabrikant implementeerde een modulair systeem dat ERP- en PLM-gegevens integreert, waardoor 80% van de ontwerpveranderingen direct opnieuw geprogrammeerd kunnen worden zonder menselijke tussenkomst.

| METRISCH | Voorafgaand aan de implementatie | Na de uitvoering |

|---|---|---|

| Dagelijkse veranderingen | 19 | 112 |

| Defectief percentage | 2,1% | 0.2% |

Het systeem behaalde:

Automatische draadsoldeermachines maken Industrie 4.0 mogelijk in sectoren die microscopische precisie vereisen. Fabrikanten van medische apparatuur gebruiken ze voor biocompatibele bedrading met 100% traceerbaarheid, terwijl leveranciers in de lucht- en ruimtevaart een nauwkeurigheid van <0,01 mm behalen.

De vraag heeft een verwachte jaarlijkse groeisnelheid van 62% voor adaptieve draadsoldeersystemen tot 2027 doen ontstaan, waarbij medische elektronica verantwoordelijk is voor 38% van de nieuwe implementaties.

Fabrikanten geven prioriteit aan de integratie van automatische soldeermachines in cellen die het volgende verwerken:

Een gefaseerde aanpak levert een 21% snellere terugverdientijd op vergeleken met landelijke implementaties.