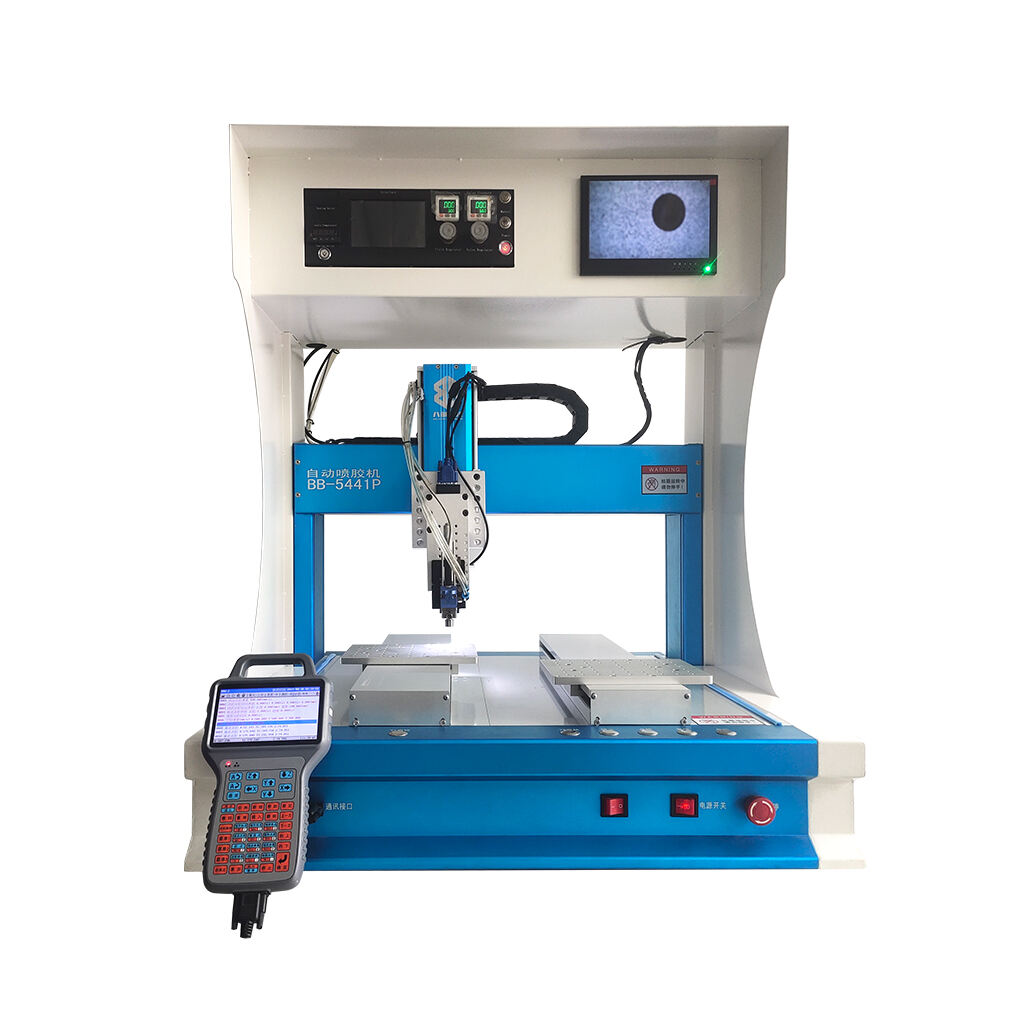

Automatic screw machines are built on essential components that drive their efficiency and precision. These machines typically feature a sophisticated feeding system that ensures a constant supply of screws and minimizes downtime. The drive mechanism, often powered by high-torque motors, supports rapid operations, while the main control unit orchestrates the entire process, offering versatile programming for diverse screw patterns. The automation mechanics behind these machines facilitate high-speed operations and ensure consistent quality in screw fastening, eliminating human error often seen in manual processes. According to a report by IndustryWeek, companies employing automatic screw machines in their production lines have witnessed productivity boosts by up to 50%, mainly due to reduced cycle times and enhanced precision. This data underscores the transformative potential of automation in modern manufacturing.

Integrating automatic screw machines with automatic screwdriver systems amplifies assembly line efficiency significantly. These machines and screwdrivers synchronize operations, allowing for smooth transitions and continuous workflows. This integration can substantially reduce labor costs, as machines handle complex tasks autonomously, eliminating the need for manual oversight. Furthermore, the precision offered by synchronized operations ensures optimal product quality, minimizing defects and enhancing customer satisfaction. In 2022, a case study by Manufacturing.net detailed how a leading electronics manufacturer successfully integrated these systems to cut assembly times by 30% and reduce error rates by 40%, showcasing the synergy of advanced automation tools in elevating production capabilities.

Precision in fastening applications is crucial, and automatic screw machines excel at delivering high accuracy. These machines dramatically lower failure rates compared to manual processes, with statistics indicating that automatic fastening yields failure rates of less than 1%, compared to over 15% in manual applications. Such superior accuracy ensures that products meet stringent quality standards, essential for industries like aerospace and electronics where precision is paramount. Automatic screw machines employ feedback loops to maintain tight tolerances, continually adjusting operational parameters to adapt to varying conditions. These loops form a critical part of the system, ensuring the machine's output remains consistent and reliable, effectively setting the benchmark for modern fastening technology.

Speed and accuracy are pivotal in meeting industrial demands, especially in the context of automatic screw machines. Speed metrics for these machines are typically quantified by the number of screws inserted per minute, with some high-performance models reaching up to 60 screws per minute. Accurate installation is crucial for maintaining production quality and avoiding defects, which can lead to costly downtime and repairs. According to experts, recent technology advancements such as enhanced drive systems and precision control units have significantly improved machine speeds without compromising accuracy, ensuring consistent and reliable outputs in high-pressure environments.

Automatic screw machines excel in versatility, allowing for seamless adaptation to various screw types and sizes. This adaptability is particularly beneficial in industries like electronics and automotive, where different assembly components require specific fastening solutions. For instance, in the electronics industry, machines capable of handling tiny, intricate screws are crucial for the assembly of devices like smartphones and computers. Moreover, modern screw machines have demonstrated up to a 30% reduction in changeover time when transitioning between screw types, enabling manufacturers to meet diverse production needs swiftly and efficiently.

Energy efficiency in automatic screw machines is a significant consideration for both environmental impact and operational cost savings. Features like variable speed drives and optimized power consumption settings contribute to less energy usage, aligning with the global push for eco-friendly manufacturing solutions. By integrating energy-efficient technologies, companies can achieve up to a 40% reduction in energy consumption, as indicated by recent industry reports. These savings not only reduce operational costs but also minimize the carbon footprint, supporting businesses in meeting sustainability goals and enhancing long-term profitability.

Calibration of automatic screw machines is an essential process that ensures accurate screw placement during production runs. By precisely aligning the machine components, calibration helps maintain consistency and precision in manufacturing operations. Typical calibration methods involve using laser sensors and precision gauges to adjust the machine axes. Advanced software tools are also commonly used, enabling operators to set parameters directly through user-friendly interfaces. Evidence from factory scenarios shows significant performance improvements following calibration, with increases in production quality and consistency. These enhancements are particularly noticeable in high-volume settings where every millimeter counts.

Implementing preventive maintenance strategies is pivotal for keeping automatic screw machines operational and efficient. Key practices include regular inspection of machine parts, lubrication of moving components, and timely replacement of worn-out parts. These actions can drastically reduce the frequency of malfunctions, thereby extending the life of the machinery. Statistics indicate that factories employing effective maintenance strategies see a significant reduction in unscheduled downtime. This proactive approach not only improves machine reliability but also enhances overall productivity, allowing for uninterrupted production runs and minimizing costly delays.

Adopting best practices for material handling is essential to minimize feed issues and enhance operational efficiency in automatic screw machines. Ensuring materials are correctly sized and pre-treated reduces the likelihood of jamming or misfeeds during operation. Ergonomic design plays a crucial role, as it helps reduce manual handling fatigue and streamline the workflow. Data on material handling errors underscores their impact on production efficiency, with poorly managed materials frequently leading to increased production costs and decreased output. Addressing these errors through improved handling techniques can lead to smoother operations and ultimately higher productivity.

Resolving issues with jammed screw feed mechanisms is crucial for maintaining smooth production processes. Common causes of jamming often include misaligned screws, worn feeders, or foreign material obstructing the pathways. A proactive approach to tackling these problems involves regular inspections and timely replacement of worn parts. For instance, conducting visual checks and using diagnostic tools can help in preemptively identifying potential jamming issues before they escalate. Industry research suggests that factories implementing regular inspections witness a 30% reduction in jamming incidents. Furthermore, insights from manufacturing experts highlight that adjusting feeder angles and ensuring proper lubrication are effective resolutions for reducing jamming frequency.

Minimizing downtime resulting from wear and tear in machine components is vital for sustaining production efficiency. Utilizing high-quality materials and parts can significantly enhance durability, thereby reducing the frequency of breakdowns. For instance, investing in premium alloy screws and robust feeders has shown to extend operational life by up to 25%. Furthermore, routine maintenance checks, involving the cleaning and lubrication of parts, play a critical role in minimizing unexpected failures. Factories that incorporate these tactics report a 40% decrease in unscheduled downtimes, underscoring the efficacy of using quality materials and regular upkeep in minimizing operational disruptions.

Adapting automatic screw machines to meet complex assembly requirements is essential for industries with diverse production needs. Recent advancements in software and technology have greatly enhanced the capabilities of these machines, enabling them to perform a wide range of applications, from electronics to automotive assembly. These enhancements include sophisticated programming interfaces and customizable components that allow machines to adjust to varying screw sizes and placements. Companies like Tesla have successfully adapted their machinery to handle multifaceted production tasks, resulting in both heightened productivity and precision. The integration of such technological advancements confirms the automatic screw machine's ability to seamlessly adapt to evolving assembly challenges across different sectors, thereby optimizing operational efficiency.

Efficient operation of automatic screw machines hinges on the development of essential operator skills. Operators must possess a deep understanding of machine components, troubleshooting techniques, and effective maintenance practices. Training programs enrich operators with these skills, leading to increases in machine efficiency and productivity. One compelling example is a case study from a manufacturing plant that witnessed a 25% increase in productivity after operators underwent skill-enhancement training. Such programs empower operators to handle complex scenarios, ultimately optimizing machine output and minimizing operational hiccups.

Safety and workflow protocols are pivotal components when operating automatic screw machines. Implementing effective safety measures not only safeguards operators from accidents but also enhances overall workflow efficiency. Examples include wearing protective gear and establishing safe zones around machines to prevent accidents. Factories with formalized protocols report a 40% reduction in accident rates as compared to those without. This significant decrease underscores the importance of a structured approach to safety and workflow management, ensuring seamless machine operation and worker safety.

Advanced machine diagnostics serve as a critical tool in predicting potential failures and optimizing machine performance. Technologies such as IoT and AI bolster diagnostic capabilities, enabling real-time monitoring and proactive maintenance strategies. For instance, IoT devices can track machine health metrics, sending alerts before issues escalate, while AI algorithms analyze data to predict performance trends. A study on the causal effects of these technologies revealed that factories leveraging IoT and AI experienced a 30% improvement in operational performance, demonstrating the transformative power of technological advancements in machine diagnostics.