Automatic hot melt adhesive machines play a pivotal role in modern manufacturing by efficiently melting solid adhesives and dispensing them in a molten state. The process begins when the adhesive is heated until it reaches its melting point, transforming it into a liquid that can be easily applied to various surfaces. Temperature control is critical to ensure that the adhesive melts optimally and remains in the desired viscosity for application. This control allows for precise regulation of the flow rate, impacting how well the adhesive performs on the surface it is applied to. Compared to traditional methods, hot melt adhesive machines offer significant benefits in terms of speed and efficiency, making them ideal for high-volume production scenarios.

Hot melt adhesive technology relies on several core principles that enable its effectiveness and versatility in industrial applications.

1. Melting and Dispensing: Hot melt adhesive machines are designed to melt solid adhesives and dispense them in a molten state, providing a reliable and consistent application. By maintaining a precise temperature, these machines ensure the adhesive remains fluid and easy to handle during the application process.

2. Temperature Control: Advanced temperature control systems are integrated into these machines to ensure precise melting and application conditions. Proper temperature management is crucial, as it affects viscosity and flow rate, which in turn impacts the bond's strength and durability.

3. Viscosity and Flow Rate: The viscosity and flow rate of the adhesive are crucial in determining the quality of the bond post-application. An optimal balance must be achieved to allow the adhesive to spread evenly and bond securely without sagging or dripping.

When compared to traditional adhesive methods, the advantages of hot melt technology become apparent, particularly in terms of speed and precision. By streamlining the adhesive application process through automation, manufacturers can achieve faster production times and reduce material wastage.

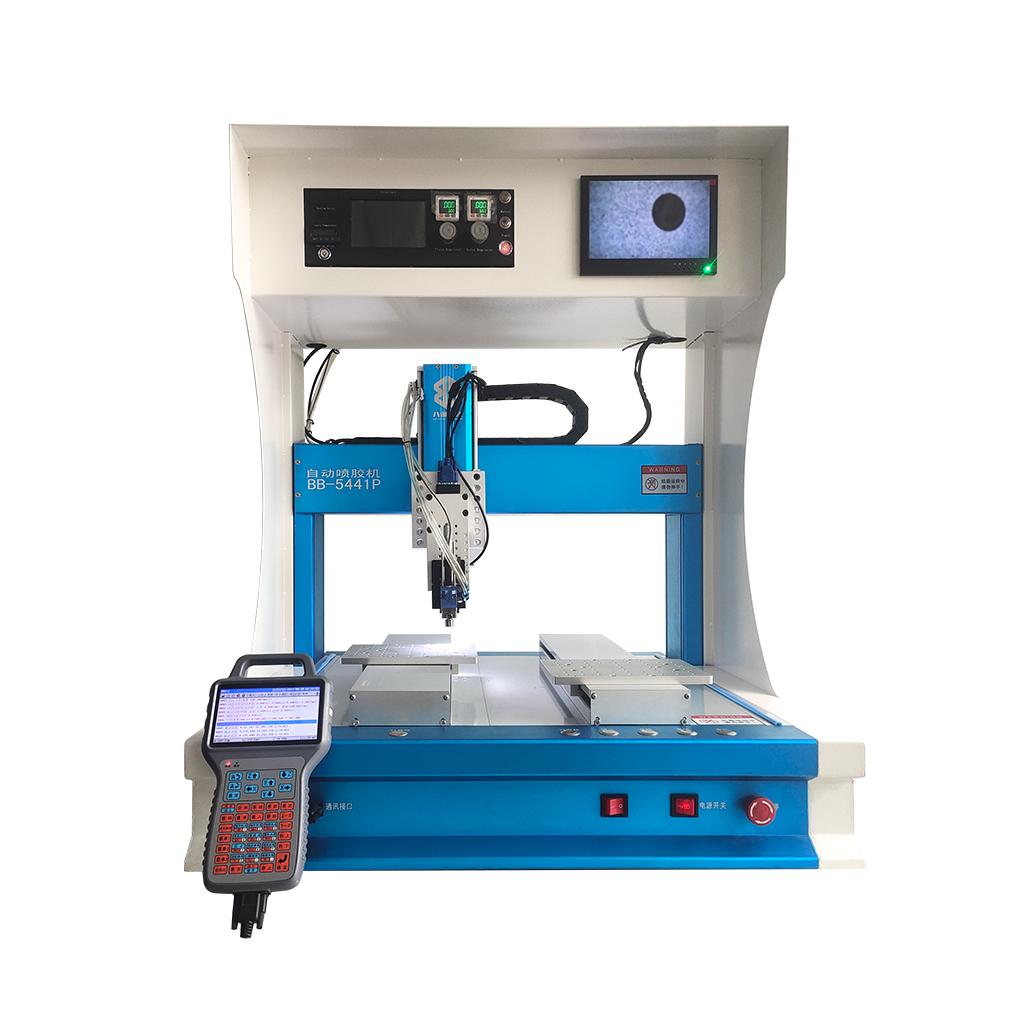

Automatic hot melt adhesive machines are comprised of several key components, each playing a critical role in ensuring precise and efficient adhesive application.

1. Dispensers: These are integral to controlling the amount and pattern of adhesive applied, enhancing the machine's adaptability to various production needs. By regulating the adhesive flow, dispensers ensure consistency in the application process.

2. Heat Control Systems: These systems maintain the necessary temperature throughout the dispensing process, ensuring the adhesive stays at the optimal viscosity for application. Precise heat control prevents premature solidification and ensures a uniform adhesive layer.

3. Robotic Components: Robotics are employed to achieve precision in the adhesive application, crucial for intricate manufacturing processes that require detailed adhesive placement. This integration allows manufacturers to enhance the consistency and quality of their products while reducing manual labor.

By combining these elements into a unified and automatic system, hot melt adhesive machines significantly increase manufacturing efficiency. This integration allows manufacturers to meet high production demands while maintaining quality standards and reducing production costs.

Automatic hot melt adhesive systems play a pivotal role in ensuring precision in adhesive placement, minimizing human error significantly. By automating this aspect, industries such as electronics, automotive, and aerospace can witness enhanced product quality and reliability. For example, electronics manufacturers can achieve accurate circuit board assembly, which enhances functionality and reduces defects. According to industry reports, implementation of these systems has led to a 20% reduction in assembly defects. Expert opinions suggest that consistent adhesive application is crucial for meeting ISO quality standards, thereby reinforcing product integrity and consumer trust.

Utilizing hot melt adhesive technology facilitates cost savings primarily through reduced material waste. The mechanism optimizes adhesive usage, thereby minimizing excess waste and cutting down overall expenditure on raw materials. Streamlined processes afforded by automatic systems tangibly shorten production cycles, which translates directly into reduced labor costs. Companies adopting hot melt systems experience substantial return on investment (ROI), backed by quantitative data showcasing a 15% improvement in profit margins over traditional adhesive application methods. The success stories of several manufacturers further underscore these economic advantages.

The integration of automatic glue dispenser machines significantly accelerates production lines, optimizing speed to cater to high-volume demands. This enhancement is pivotal for industries like packaging and textiles, which thrive on rapid production schedules. Statistical data indicates a 30% increase in production capacity following the incorporation of hot melt machines into manufacturing processes. This efficiency not only meets current market demands but positions manufacturers for future scalability as consumer demand for quick product turnover continues to rise. This forward-looking approach fosters readiness for expanded production capabilities in an evolving marketplace.

Hot melt adhesives are integral in electronics, especially for securing components on circuit boards. This adhesive type ensures that components remain firmly attached, minimizing the risk of dislocation due to vibrations or temperature changes. Using hot melt technology in electronics aids in reducing assembly time, significantly improving production efficiency. Electronics manufacturing demands specific adhesion properties due to the delicate nature of circuit boards and components. Unlike other industries, electronics require adhesives that provide precision without extra bulk. Industry reports have highlighted a notable increase in the application of hot melt technology within electronics, underscoring its role in enhancing production capabilities while ensuring product reliability.

Hot melt adhesives play a crucial role in maintaining the integrity of packaging materials, acting as a reliable sealant that ensures products remain secure during transport and storage. Implementing automated sealing systems bolsters efficiency along packaging lines by reducing manual intervention and facilitating faster operations. This results in consistent sealing performance, boosting the durability and appearance of packaged goods. Statistical data suggests a growing trend in adopting hot melt adhesives within packaging, as they enhance sealing accuracy and reliability. Numerous companies have successfully streamlined their packaging processes with these technologies, illustrating the adaptability and widespread benefits of automated systems in modern manufacturing.

The application of hot melt adhesives in automotive manufacturing, particularly in bonding interior components, is transformative. This adhesive solution meets the rigorous performance requirements of the automotive sector, where durability and resistance to wear are paramount. Such adhesives are pivotal for secure assembly in vehicle trims and interiors, contributing to both safety and aesthetic appeal. Market trends reveal an increasing reliance on adhesives within vehicle manufacturing, driven by demands for efficiency and innovation. Experts anticipate further developments, emphasizing sustainability and longevity, to drive the future of automotive adhesives, with hot melt solutions at the forefront due to their versatility and environmental advantages.

The integration of IoT technology in automatic glue dispenser machines is revolutionizing their functionality and efficiency. By embedding IoT components, these systems can achieve unmatched connectivity features, allowing for real-time monitoring and control. This translates to increased precision in adhesive application and the ability to maintain optimal machine performance. For instance, smart dispensers—equipped with sensors—can monitor adhesive levels and dispense exact amounts, thereby minimizing waste and ensuring quality adherence. Looking forward, IoT connectivity can pave the way for predictive analytics in manufacturing. This would enable us to anticipate machine needs and maintenance schedules, reducing unplanned downtime and enhancing overall productivity.

AI technology is fundamentally transforming the landscape of hot melt adhesive applications by enabling real-time quality monitoring and predictive maintenance. Through AI, systems can analyze adhesive application patterns to detect anomalies or deviations instantly, ensuring unprecedented quality control. Predictive maintenance strategies powered by AI further reduce downtime by anticipating potential issues and optimizing repair cycles before they disrupt operations. By incorporating AI into our processes, companies can enjoy substantial cost benefits, such as reduced wastage and enhanced operational efficiency. Several industry leaders leverage AI for these purposes, reporting marked improvements in their production line performance and outcome quality. This trend highlights the immense potential of AI-driven methodologies in shaping the future of manufacturing technologies.