Energy-efficient hot melt adhesive machines significantly reduce operational costs through advanced thermal systems. These systems effectively utilize insulation technologies, minimizing heat loss and achieving energy savings of up to 30%. By incorporating high-efficiency heaters, these machines also curb electricity consumption, resulting in lower utility bills. Importantly, case studies demonstrate that an investment in such technology can often be recouped within two years, owing to the substantial reduction in energy usage. This makes the shift to energy-efficient hot glue dispensing machines not just environmentally beneficial, but financially prudent as well.

Implementing precision heating technologies in automatic glue dispensers plays a crucial role in reducing material waste and minimizing downtime expenses. By maintaining the adhesive at its ideal temperature, these technologies prevent waste caused by overheating or incorrect viscosity. Smart monitoring systems further enhance efficiency by alerting operators to potential failures before they occur, thereby extending the machinery’s lifespan. The bottom line is that material costs can decrease by up to 20%, leading to improved profit margins and more efficient hot melt operations.

Embracing energy-efficient hot melt glue machines translates into long-term savings by substantially lowering operational expenditures, with a potential reduction in energy costs of approximately 25%. By calculating the total cost of ownership, businesses can clearly see how the returns from modern adhesive machines surpass those of older models. Industry leaders often underscore the significance of considering return on investment when deciding on new equipment. Thus, transitioning to energy-efficient glue dispenser machines is not just a cost-saving measure but a strategic investment for sustained profitability.

Precision temperature control systems are integral to maintaining adhesives at their ideal viscosity, optimizing performance and minimizing wastage. These systems use technologies like PID controllers to maintain a consistent temperature, which is essential for achieving high-quality finishes in manufacturing. Vendors have reported that employing these technologies can lead to a 15% increase in adhesive application efficiency, allowing less trial and error and more precise viscosity adjustments.

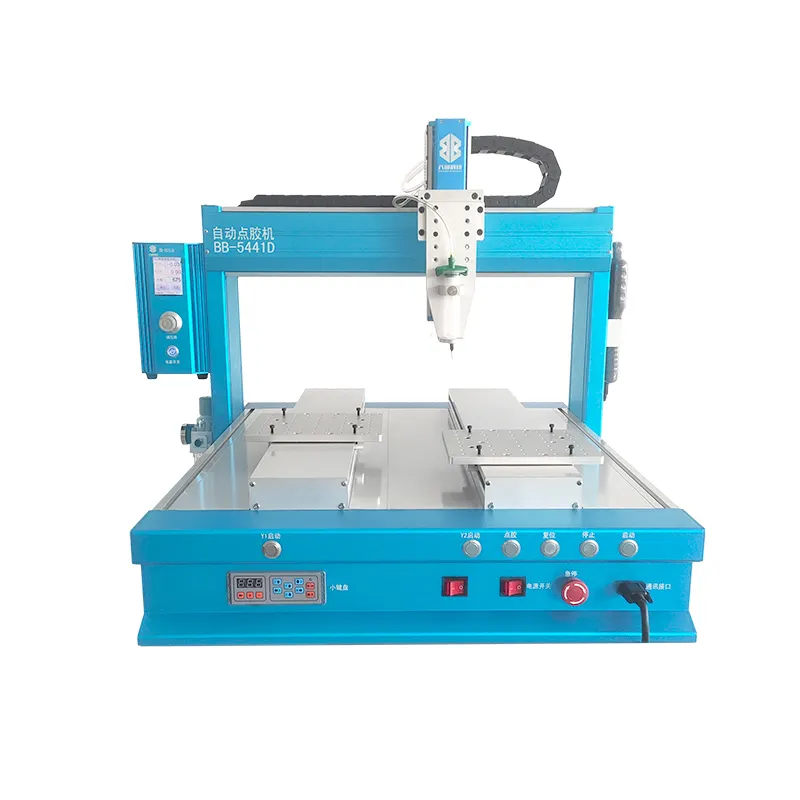

Equipping automated glue dispensers with AI algorithms allows for real-time adjustment of glue application based on substrate requirements, thereby enhancing both efficiency and precision. Case studies from various factories demonstrate that these smart dispensers can achieve a 30% reduction in glue consumption while simultaneously increasing production speeds. Integration of sensors and data analytics provides valuable real-time feedback to optimize the dispensing process further, ensuring consistent and high-quality output.

Eco-smart designs in hot glue dispensing machines focus on sustainability by incorporating energy-efficient motors and recyclable materials, reinforcing sustainability initiatives within manufacturing sectors. These designs often adhere to stringent environmental regulations, significantly reducing ecological impact. Data indicates that companies adopting eco-smart technologies can notably lower their emissions, helping align their operations with global sustainability goals.

Implementing robust preventive maintenance schedules is essential to preempt machinery failures and minimize unexpected downtimes, significantly enhancing operational efficiency. By conducting regular checks on systems such as temperature calibration and diagnostics, hot melt adhesive machines can maintain optimal performance. According to industry research, facilities that adhere to rigorous maintenance protocols report up to 40% fewer operational disruptions, making a compelling case for strategic upkeeps. This ensures that operations remain smooth and productive, avoiding the costly consequences of unplanned repairs or replacements.

Training operators in energy-efficient practices is crucial in fostering a culture of sustainability within manufacturing environments. Comprehensive training programs that focus on effective machine operation can lead to a substantial 20% reduction in energy waste. Expert consultations further highlight that continuous training is imperative to ensure operators are updated with advancements in adhesive technology. The knowledge gained from these programs not only optimizes machine performance but also contributes to overall energy conservation, thereby aligning manufacturing practices with modern sustainability goals.

Choosing the right adhesives for low-temperature processing can drastically reduce energy consumption and operational costs. Specialized adhesives that perform effectively at lower temperatures minimize the need for extensive heating, translating to significant cost savings. Industry standards suggest that using low-temperature adhesives not only enhances machinery longevity but also decreases overall operational costs. This strategic selection is vital for optimizing the eco-efficiency of manufacturing processes and supporting sustainability initiatives in the industry.

Adopting energy-efficient hot melt adhesive machines plays a vital role in reducing the carbon footprint in manufacturing processes. These machines are designed to consume less energy, resulting in lower greenhouse gas emissions. Studies from environmental organizations indicate that by integrating modern manufacturing practices, carbon emissions can be diminished by as much as 35%, which is substantial progress toward sustainability goals. Furthermore, companies that invest in sustainable machinery often find that it strengthens their presence in eco-conscious markets, appealing to environmentally aware consumers and enhancing their corporate image.

Across various regions, there is an increasing trend toward the utilization of automated glue dispensers, driven by the need for enhanced precision and reduced labor costs. Market analysis shows that regions adopting such automated systems are experiencing productivity increases of up to 50%. This shift is encouraged by government initiatives aimed at promoting automation in manufacturing sectors. Automated glue dispensers not only streamline operations but also contribute to consistent product quality, reinforcing their appeal to manufacturing businesses eager to improve efficiency and competitiveness.

The field of hot melt adhesive technology is on the brink of significant innovations that promise to boost efficiency and reduce environmental impacts. Recent advancements in material science suggest the potential for new adhesive formulations that offer superior strength while being more energy-efficient. Industry forecasts predict an upsurge in investment toward research and development in this area, with a focus on sustainable production methods. These innovations are expected to revolutionize the adhesive industry, making it more sustainable and economically viable in the long term.