Achieving high precision in manufacturing processes is a complex challenge, especially in industries reliant on adhesive applications. Precision in manufacturing is crucial because even minor misalignments or inconsistent adhesive application can lead to product defects, decreasing reliability and increasing financial losses. Statistics show that such issues can result in significant economic impacts, with manufacturers often bearing high costs due to rework or product recalls. For instance, misalignment in electronics can lead to malfunctioning devices, impacting consumer trust and brand reputation. Emphasizing precision, especially in glue dispensing, can dramatically improve product quality and reliability, making it a critical focus in modern manufacturing. Integrating advanced systems, like automatic glue dispensers, becomes essential to address these challenges effectively.

Automatic glue dispensers ensure uniformity in adhesive application, mitigating the inconsistencies often experienced with manual processes. By incorporating automated systems, like those in the automotive and electronics industries, manufacturers enhance operational efficiency and reduce variability in product output. For example, an automatic glue machine precisely controls the quantity of glue laid down, ensuring every joint or seal is uniformly strong. A study conducted in the electronics sector showed error rates in adhesive applications reduced by up to 60% with the use of automated glue dispensing machines compared to manual methods. Such advancements significantly diminish the risks associated with manual glue application, particularly misalignment and uneven distribution. Ultimately, automation in manufacturing bolsters consistency in glue dispensing, improving overall product quality and reducing the likelihood of costly errors.

The integration of intelligent metering systems in automatic glue dispenser machines has been transformative, enabling precise measurement of adhesives to ensure application accuracy. These technologies use advanced algorithms and real-time data processing to adjust the amount of adhesive dispensed, considering variables such as viscosity and ambient temperature. Moreover, mixing systems play a critical role in maintaining the homogeneity of adhesives, which significantly improves adhesion properties by preventing separation or inconsistencies during application. Manufacturers have reported enhanced performance through intelligent metering, with case studies highlighting improvements in both product quality and operational efficiency. These advancements not only optimize the adhesive application process but also contribute to reducing waste and increasing overall production reliability.

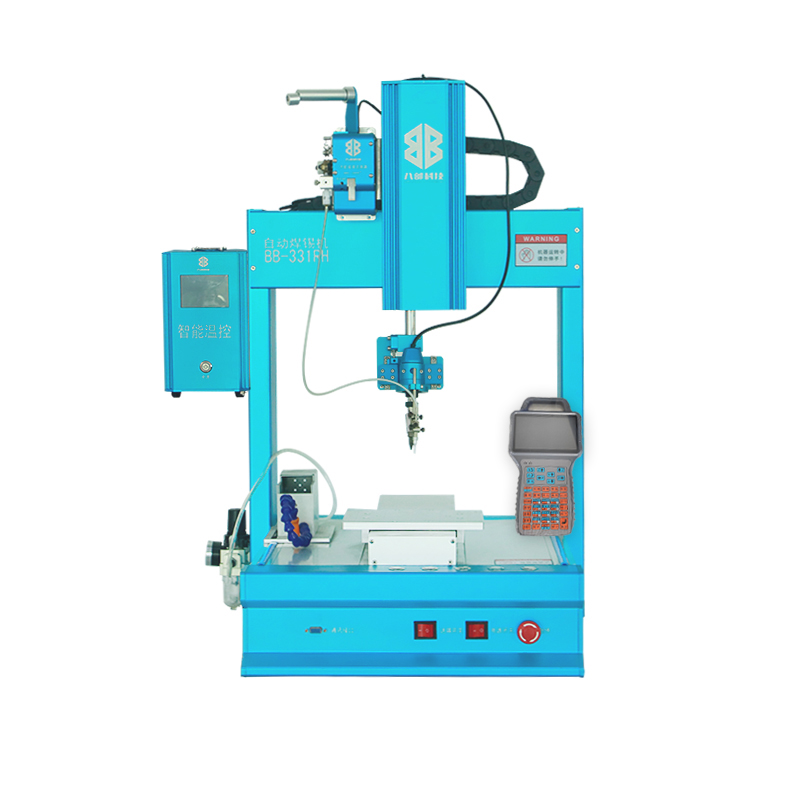

The high precision required in automatic glue dispensing is largely achieved through advanced valve and control technologies, which precisely regulate flow rates and pressure. Valves such as needle and diaphragm types are commonly used for their ability to maintain stable flow, even under varying operational conditions. In combination with cutting-edge control systems, these valves enable real-time monitoring and adjustments during the dispensing process, ensuring consistency and reliability. Technological breakthroughs, like the incorporation of IoT-enabled sensors, have further enhanced operational reliability by facilitating predictive maintenance and minimizing downtime. These control technologies adhere to stringent industry standards, thereby optimizing glue dispensing systems to meet the demanding requirements of modern manufacturing environments.

Automatic glue dispensers play a crucial role in the electronics industry, particularly in the assembly of printed circuit boards (PCBs). These devices ensure precision, reliability, and consistency when applying adhesives, vital to creating reliable electronic products. Automatic glue dispensers are used to secure components, such as capacitors and microchips, to PCBs, improving manufacturing efficiency and quality. In this high-demand sector, the precise application of adhesives minimizes the risk of defects, ensuring product reliability. For example, smartphones and computers—which require meticulous adhesive deployment—benefit significantly from automated glue dispensing systems. Industry data suggests a notable uptick in automated solution adoption, driven by the pursuit of streamlined production processes and heightened demand for high-performance devices.

In the automotive sector, automatic glue dispensers are pivotal for bonding and sealing components, ensuring structural integrity and meeting stringent safety standards. These dispensers are used extensively in the production of various automotive components, including interior panels and external body parts. The automation of adhesive application helps manufacturers achieve consistent quality and safety compliance, enhancing the durability and performance of vehicles. According to industry reports, the integration of automated dispensing machines in automotive production lines has boosted operational efficiency, reduced costs, and contributed to significant environmental benefits by minimizing material waste. With increasing emphasis on electric and autonomous vehicles, the reliance on precise adhesive application continues to grow, highlighting the indispensable role of glue dispensers in modern automotive manufacturing.

In the realm of glue dispensing automation, precision is paramount. Key performance indicators (KPIs) such as accuracy, repeatability, and throughput are instrumental in measuring the improvements brought by automatic glue dispensers. Industries transitioning from manual to automated methods often report enhanced precision through reduced human error and consistent adhesive application. Metrics like reduced cycle times and increased yield rates serve as proof of the quantifiable benefits of these systems.

Various sectors utilize these metrics to benchmark performance improvements. For instance, in electronics manufacturing, automatic glue dispensers significantly reduce component failure rates, adhering to strict tolerances and quality standards. Experts emphasize the statistically significant precision achieved with automation, observing improvements of up to 30% in adhesive application consistency. This advancement, corroborated by industry research, underscores the operational efficiency realized through automated dispensing solutions.

The long-term cost efficiencies of transitioning to automatic glue dispensing cannot be overstated. Companies can achieve substantial savings on materials and labor, reducing waste and enhancing operational efficiency. Automating glue dispensing processes diminishes the need for manual labor, which, over time, results in decreased personnel costs and minimized material waste due to precise application.

Initial investments in automatic systems, though significant, are often offset by operational savings accumulated over time. A financial analysis in the industry might show that companies recover their investments within two to three years owing to considerable reductions in direct costs. Case studies reveal that firms implementing automated systems have cut dispensing-related expenses by nearly 40%, highlighting the profound financial benefits of embracing automation. As such, the cost savings gained from automatic glue dispensers not only improve the bottom line but also enable companies to reinvest in other crucial areas for growth.