Ang mga gumagawa ng elektronika ay tumawid na sa puntong hindi na maaaring ibalik: Ochenta't tatlong porsiyento ng mga industrial OEM noong huli'y hinilingan ng mga analyst ng IDC ay umaasa sa mga batch-specific wire configurations (Ponemon 2023). Ang HMLV (High Mix, Low Volume) na pagmamanupaktura ay isinasagawa ito nang eksakto sa pamamagitan ng mga flexible workflow na idinisenyo para sa patuloy na pagbabago ng produkto sa paraang salungat sa mass production. Ito ay napatunayang isang napakalaking pagbabago dahil ang mga awtomatikong makina sa pag-solder ng wire ay naging kritikal na sandata at kayang hawakan ang higit sa 100 iba't ibang uri bawat araw nang hindi nasasakripisyo ang katumpakan.

Mga merkado mula sa mga medikal na implant hanggang sa industrial IoT ay nangangailangan ng mga solusyon sa wiring na inaayon sa partikular na toleransiya sa boltahe, limitasyon sa espasyo, at mga kondisyon sa kapaligiran. Halimbawa:

Ginagawang hindi naaangkop ng pagbabagong ito ang dating 10,000-unit na mga batch ng produksyon. Ang mga manufacturer ay gumagawa na ngayon ng mabilis na prototyping cycles—kung saan ang paglipat mula sa CAD design patungo sa mga functional samples ay nangyayari sa loob lamang ng 8 oras sa ilang kaso.

Nahihirapan ang manu-manong wire soldering na mapanatili ang <0.5% na rate ng depekto kapag kinakausap ang 5-10 pagbabago ng disenyo bawat shift. Ang mga karaniwang isyu ay kinabibilangan ng:

| Hamon | Epekto | Automatikong Solusyon |

|---|---|---|

| Mga hindi magkakatulad na solder joint | 6.5% na pagtaas ng field failure rate | Closed-loop thermal control |

| Mga maling konpigurasyon | 12-18 minutong paggawa muli sa bawat pagkakamali | Pagpapatunay sa pamamagitan ng RFID ng toolhead |

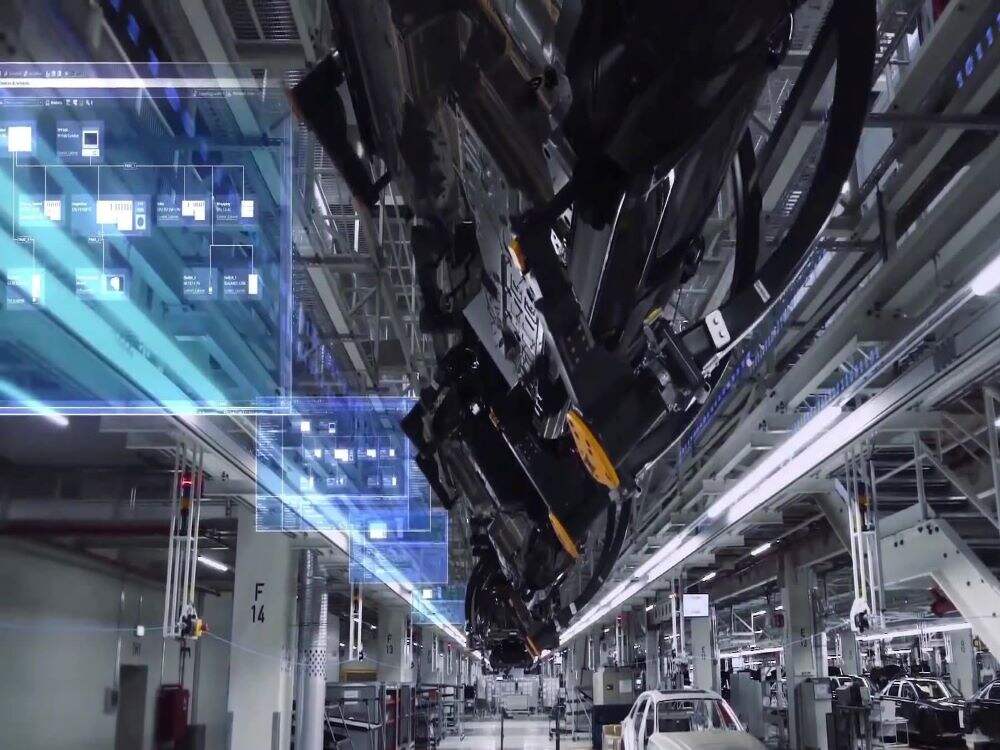

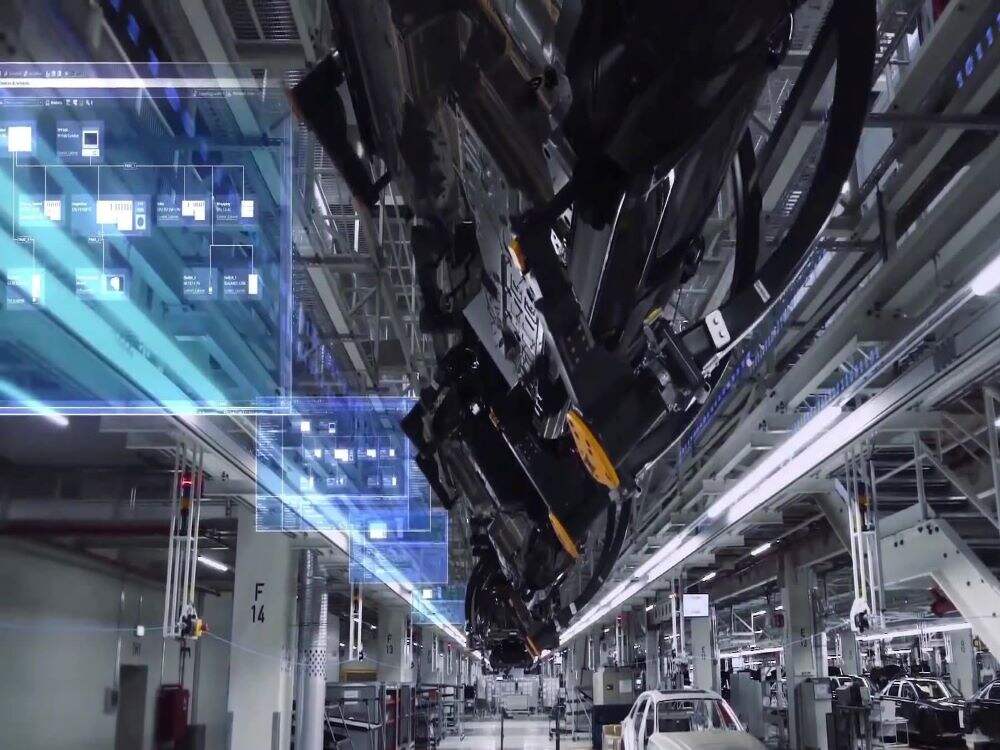

Ang paglipat ng industriya ng sasakyan patungo sa mga EV na ginawa-sa-order ay nagpapakita ng kahalagahan nito—ang mga nangungunang tagagawa ay nakakamit ng 112 beses na pagbabago sa disenyo araw-araw gamit ang modular na sistema ng awtomatikong pag-solder ng kable.

Ang ekonomiya ng mass production ay nagiging hindi epektibo sa ilalim ng 500 yunit na batch—ang mga gastos sa pag-setup ay umaabos ng 72% ng presyo bawat yunit kumpara sa 9% sa mga HMLV-optimized na cell. Ang isang batch ng 50 prototype na bahagi sa kable ng sasakyan ay nangangailangan ng:

Tradisyonal na Linya

HMLV Automation

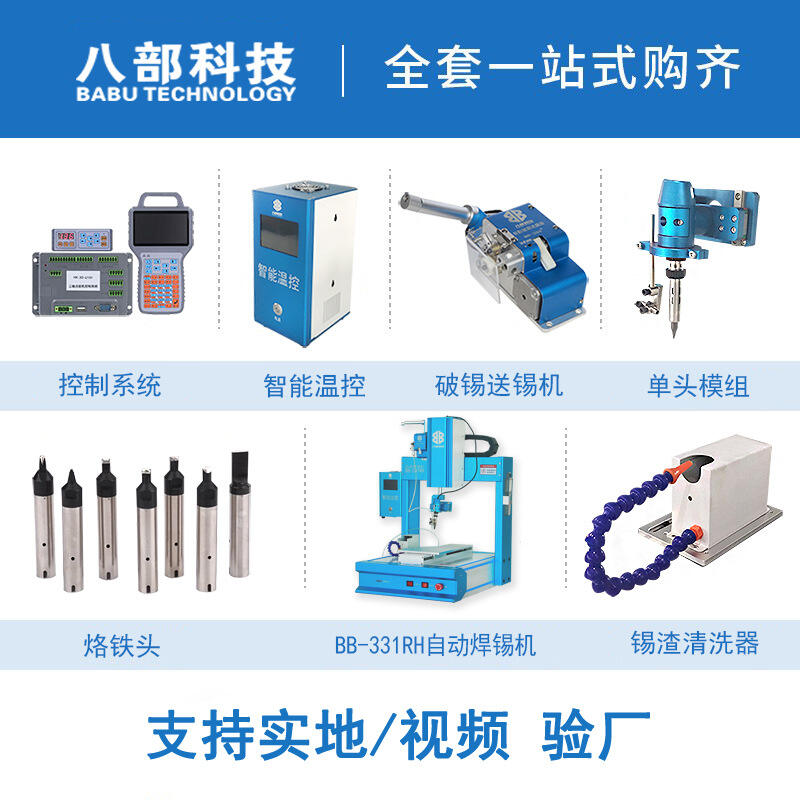

Ang mga awtomatikong makina sa pag-solder ng kable ay nakatutok sa mga modernong hamon sa inhinyerya sa pamamagitan ng pagpapahintulot sa muling pagsasaayos sa totoong oras nang hindi naghihintay sa produksyon. Ang mga sistemang ito ay direktang nakakabit sa mga platform tulad ng CAD/CAM tulad ng Autodesk Fusion 360 upang mai-convert ang mga na-update na disenyo sa mga maisasagawang utos sa loob lamang ng ilang minuto.

Ang katiyakan ng mga sistema ng adaptibong kontrol ay nagsisiguro na ang bawat solder joint ay mapapanatili ang ±0.01mm na katumpakan sa posisyon, kahit kapag kinokontrol ang:

Ang mga modernong awtomatikong makina sa pag-solder ng kable ay umaabot sa pinakamataas na pagganap sa pamamagitan ng mga adaptibong sistema ng kontrol na patuloy na namamonitor at pino-pino ang mga variable ng produksyon.

Ang mga adaptive na sistema ng soldering ay gumagamit ng multi-sensor arrays upang subaybayan ang temperatura (±1°C), dami ng solder (±0.01 ml), at pagkakatugma ng joint (5μm na katumpakan). Kapag may paglihis, ginagawa ng closed-loop system ang mga pagwawasto sa loob lamang ng 50ms—mas mabilis kaysa makita ng mga operator na tao ang mga pagkakamali.

Mga pangunahing kakayahan:

Ang mga deep learning algorithm ay nag-aaral mula sa nakaraang datos ng proseso at mga resulta ng real-time na inspeksyon upang mahulaan ang katiyakan ng joint. Na-train sa higit sa 850,000 solder connections, ang mga modelong ito ay nakakamit ng 94% na katumpakan sa pagtaya ng mga joint na may posibilidad na magkamali bago pa man ang electrical testing.

| Yugto ng Proseso | Traditional Method | ML-Enhanced Method |

|---|---|---|

| Pagtuklas ng depekto | Mga pagsusulit pagkatapos ng produksyon | Mga real-time na pagtataya |

| Rate ng Maling Positibo | 12% | 2.8% |

Ang mga adaptive controller ay awtomatikong nagre-reconfigure ng mga parameter ng makina para sa iba't ibang disenyo ng wiring harness, binabawasan ang downtime sa changeover ng 78% kumpara sa mga manual na pamamaraan.

Nagkaroon ng mga hamon ang isang nangungunang manufacturer ng medical device na may 1,200+ wiring harness SKUs at kahusayan sa forecast ng demand na nasa ilalim ng 42%. Dahil sa tradisyonal na batch production, nawala ang 23% na mga bahagi bago pa man gamitin.

Ipinatupad ng manufacturer ang isang modular system na nag-i-integrate ng datos mula sa ERP at PLM, na nagbibigay-daan sa agarang reprogramming para sa 80% ng mga pagbabago sa disenyo nang walang interbensyon ng tao.

| Metrikong | Bago ang Pagpapatupad | Pagkatapos ng Pagpapatupad |

|---|---|---|

| Araw-araw na Mga Pagbabago | 19 | 112 |

| Rate ng Defektibo | 2.1% | 0.2% |

Nakamit ng sistema:

Ang mga kagamitang awtomatikong magsolder ng kable ay nagpapagana ng Industry 4.0 sa mga sektor na nangangailangan ng microscopic precision. Ginagamit ito ng mga tagagawa ng medikal na kagamitan para sa biocompatible wiring na may 100% na traceability, samantalang ang mga supplier ng aerospace ay nakakamit ng <0.01mm na katumpakan.

Ang demand ay nagdulot ng inaasahang 62% na compound annual growth rate para sa mga adaptive wire soldering system hanggang 2027, kung saan ang medikal na elektronika ay nagkakamit ng 38% ng mga bagong paglulunsad.

Inuuna ng mga manufacturer ang integrasyon ng automatic soldering machine sa mga cell na nagpo-proseso ng:

Ang isang phased approach ay nagdudulot ng 21% mas mabilis na ROI kumpara sa enterprise-wide rollouts.